-

manufacturing technology 1moulding sands types

Moulding Sand: Green sand is an aggregate of sand, bentonite clay, pulverized coal and water. Manufacturing Process Meaning Types Casting, Froming what is manufacturing process, in this article find meaning and types of manufacturing process casting, forming, joining and machining Beside above, all the future technicians must understand ...

Get Price -

Kevlar Fiber: Types, Properties, Manufacturing Process and ...

· Kevlar is an organic fiber in the aromatic polyamide family. Kevlar has unique combination of high strength, high modulus, toughness and thermal stability. It was developed for demanding industrial and advancedtechnology appliions. Currently, many types of Kevlar are produced to meet a broad range of end uses.

Get Price -

Sand

Sand Designing Buildings Share your construction industry knowledge. Sand is a type of naturally occurring material that is of a granular, loose, fragmented composition, consisting of particulate matter such as rock, coral, shells, and so on. Sand is typically finer than gravel but coarser than silt.

Get Price -

mechanical engineering: Moulding sand properties and its types

1: porosity or permeability. It is the property of sand which permits the steam and other gases to pass through the sand mould. The porosity of sand depends upon its grain size, grain shape, moisture and clay components are the moulding sand. If the sand is .

Get Price -

Types of Sand: Uses, Properties, Grain size ...

Types of Sand Classifiion of Sand. Followings are the classifiion of Sand: Based on the grain size of the particle, sand is classified as Fine Sand( to ), Medium Sand( to 2mm), and Coarse Sand( mm to ) Based on origin, sand is classified as Pit sand, River sand, Sea sand, and manufactured sand.

Get Price -

Manufactured Sand vs. Natural Sand

· The choice of fine aggregate, whether it is manufactured or natural sand, can greatly impact the fresh concrete properties of a mixture such as the workability, pumpability, and finishability. Natural sand has an ideal shape for use as fine aggregate in concrete. The natural sand particles are wellrounded and are usually nearly spherical.

Get Price -

Properties of Concrete Made with Manufactured Sand

The University of Queensland's institutional repository, UQ eSpace, aims to create global visibility and accessibility of UQ's scholarly research.

Get Price -

Properties of Cement

· Cement is the most demanded construction material which is easily available in the local market all over the world. Every year thousands of tons of cement are produced to meet the demands of construction industry. Historically, lime and volcanic ash was used as an adhesive in construction, but nowadays cement has become most recognized adhesive material and used .

Get Price -

Physicochemical properties of quartz from industrial ...

Here, modifiions affecting a quartzrich sand during cast iron production, have been investigated. Composition, morphology, presence . Physicochemical properties of quartz from industrial manufacturing and its cytotoxic effects on alveolar macrophages: The case of green sand mould casting for iron production ...

Get Price -

Properties of Cast Magnesium Alloys

AZ91C is used in sand and permanent mold castings when maxim corrosion resistance is not required. Corrosion Resistance ASTM B 117 Salt spray test AZ91D: less than mg/cm 2 /day (less than 10 mils/yr). AZ91ET6: less than mg/cm 2 /day (less than 50 mils/yr). Mechanical Properties Tensile properties See Tables 27 and 28. Shear strength

Get Price -

Mechanical and material properties of castings produced ...

· Additive manufacture of sand molds via binder jetting enables the casting of complex metal geometries. Various material systems have been created for 3D of sand molds; however, a formal study of the materials' effects on cast products has not yet been conducted. In this paper the authors investigate potential differences in material ...

Get Price -

How sand is made

Sand is used to provide bulk, strength, and other properties to construction materials like asphalt and concrete. It is also used as a decorative material in landscaping. Specific types of sand are used in the manufacture of glass and as a molding material for metal casting. Other sand is used as an abrasive in sandblasting and to make sandpaper.

Get Price -

Manufacturing Process

Manufacturing processes are explained in detail. The basic concepts of how to produce manufactured items. Describes the different manufacturing processes and the methods and techniques involved in each of these processes. Discusses the primary consideration and goals in manufacturing. How material properties relate to manufacturing process.

Get Price -

Properties of Cement Physical Chemical

Chemical Properties of Cement. The raw materials for cement production are limestone (calcium), sand or clay (silicon), bauxite (aluminum) and iron ore, and may include shells, chalk, marl, shale, clay, blast furnace slag, slate. Chemical analysis of cement raw materials provides insight into the chemical properties of cement.

Get Price -

An Investigation into the Use of Manufactured Sand as a ...

· Manufactured sand differs from natural sea and river dredged sand in its physical and mineralogical properties. These can be both beneficial and detrimental to the fresh and hardened properties of concrete. This paper presents the results of a laboratory ...

Get Price -

What Is M Sand?

M Sand Properties. Environmental Friendly – Since it has been manufactured artificially from the rock particles, it is less harmful to the environment compared to river sand. Quality of material – The quality of the sand can be controlled during its manufacturing process so the particles are well balanced in quality.

Get Price -

Advantages and Disadvantages of Manufactured Sand (MSand)

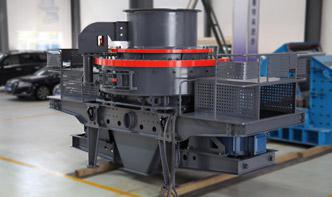

· M Sand is an ecofriendly and affordable alternative to river sand. MSand is manufactured by crushing rocks, quarry stones into sandsized particles. Because of its ready availability and reliable strength, MSand has quickly found wide usage in the construction industry. Manufacturing process of MSand. MSand is manufactured in a three stage ...

Get Price -

A Comparison of Manufacturing Technologies in the ...

These connecting rods were cast in green sand molds, annealed at 1750 oF for 18 hours and air cooled. After air cooling they were reheated a second time at 1600 oF, quenched in oil to form a martensitic microstructure and then tempered for 3 to 4 hours at oF. The reported properties for this part were: a 100 ksi minimum tensile

Get Price -

manufacturing processes properties of sand

Manufacturing of Brick Brick Industry Association. Dec 9, 2006 ... Brick shrink during the manufacturing process as vitrifiion ... Sandfinished surfaces are typical with molded brick. ... A more complete knowledge of raw materials and .

Get Price